Product Details

Description

POWERWELD STAINARC 316L-16 STAINLESS STEEL ELECTRODE:

POWERWELD牌子STAINARC 316L-16不锈钢电焊条:

DESCRIPTION:

描述:

- Rutile/ Moisture Resistance Coating.

- All Positional, Low C Deposit.

- For the Critical Welding Of Type 316 and 316L Stainless Steel.

New generation STAINARC 316L is an extra low carbon, rutile type electrode exhibiting superior all positional (except vertical down) performance with improved moisture-resistant coating for weld metal of high radiographic integrity. The smooth arc action of STAINARC 316L together with low spatter and excellent slag control/ detachability promote exceptional weld appearance and profile. Other features include high arc stability and easy restriking.

STAINARC 316L deposits a straight 19% Cr / 12% Ni / 2.3% Mo filler metal to meet the requirements for welding AlSi type 316 and 316L stainless steels in critical applications. STAINARC 316L is also recommended for the general-purpose welding of common 300 series stainless steels such as 301, 302, 304 and 304L.

- 金红石/防潮涂层。

- 所有位置的低C沉积。

- 用于316和316L型不锈钢的关键焊接。

新一代STAINARC 316L是一种超低碳金红石型焊条,具有所有位置(垂直向下除外)的优异性能,并具有改进的防潮涂层,可用于具有高射线照相完整性的焊缝金属。 STAINARC 316L的平滑电弧作用,低飞溅和出色的熔渣控制/ 可分离性可提高焊接外观和轮廓。其他功能还包括高电弧稳定性和易于重新点火。

STAINARC 316L可以沉积19%的铬 / 12%的镍 / 2.3%的钼填充金属,以满足关键应用中铝硅316和316L不锈钢的焊接要求。STAINARC 316L也建议用于普通300系列不锈钢的通用焊接,例如301、302、304和304L。

CHARACTERISTICS:

特征:

| TYPICAL ALL WELD METAL COMPOSITION (Wt%) 典型的全焊接金属成分(重量%) | |||||

| C 碳 0.025 | Mn 锰 0.7 | Si 硅 0.7 | Cr 铬 18.5 | Ni 镍 12.0 | Mo 钼 2.3 |

| TYPICAL ALL WELD METAL MECHANICAL PROPERTIES 典型的全焊接金属力学性能 | |||

| YIELD STRESS (N/mm2) 屈服强度(牛/平方毫米) | TENSILE STRENGTH (N/mm2) 拉伸强度(牛/平方毫米) | ELONGATION (%) 距角(%) | CVN IMPACT VALUES 夏比V型冲击韧性 |

| 400 | 610 | 38 | 75J @ -20°C 75焦耳@ -20摄氏度 |

* in “as welded” condition.

“处于焊接状态”

TECHNICAL DATA:

技术数据:

* Recommended for DC + or AC (minimum 45 OCV) operation.

建议用于直流电+或交流电(最少45开路电压)操作。

Additional information

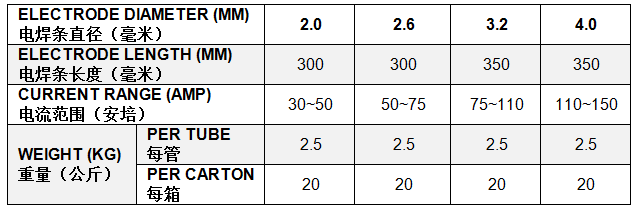

| ELECTRODE DIAMETER | 2.0MM, 2.6MM, 3.2MM, 4.0MM |

|---|---|

| WEIGHT | 2.5KG PER TUBE, 20KG PER CARTON |