Product Details

Description

POWERWELD HARDFACING ARC 43 HARDSURFACING ELECTRODE:

POWERWELD牌子硬质弧43硬表面电焊条:

DESCRIPTION:

描述:

- Tough, Wear Resistant Complex Carbide Type Deposit.

- For Hard Surfacing Components Subjected to Extreme Abrasion and Moderate to Heavy Impact.

HARDFACING ARC 43 is a heavy coated, hard surfacing electrode depositing extremely hard, abrasion-resistant Chromium/Niobium carbides in an austenitic matrix. It is ideal for hard surfacing applications where resistance to extreme abrasion (in particular sliding abrasion) and moderate to heavy impact are required. Due to the modular shape of the complex carbides, HARDFACING ARC 43 deposits are capable of withstanding heavier impact levels than standard chromium carbide grades. Typical applications include bucket teeth/lips, press screws, crusher hammers and ripper teeth to name a few.

- 坚韧耐磨的硬质合金型矿床。

- 适用于经受极度磨损和中度严重冲击的硬质表面组件。

HARDFACING ARC 43是一种重涂层,硬表面焊条,可在奥氏体基体中沉积极硬的耐磨铬/铌碳化物。对于要求耐极端磨损(特别是滑动磨损)和中度到重度冲击的硬质表面应用而言,它是理想的选择。由于复合碳化物呈球状,因此HARDFACING ARC 43镀层能够承受比标准碳化铬等级更高的冲击强度。典型的应用包括铲斗齿/唇、压紧螺钉、破碎锤和裂土器齿等等。

DEPOSIT PROPERTIES:

沉淀性质:

HARDFACING ARC 43 deposits are non-machinable, grindable, and prone to fine relief checking and should be restricted to 3 layers high. While two layers of HARDFACING ARC 43 may be required for maximum wear resistance, this complex carbide alloy has lower dilution sensitivity than straight chromium carbide deposits.

HARDFACING ARC 43沉积物不可机器加工的、不可磨削、易于细浮雕检查,应限制在3层高。虽然可能需要两层HARDFACING ARC 43才能获得最大的耐磨性,但这种复杂的碳化物合金的稀释敏感性要比纯碳化铬沉积物低。

TECHNICAL DATA:

技术数据:

Additional information

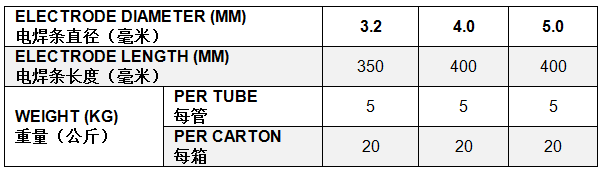

| ELECTRODE DIAMETER | 3.2MM, 4.0MM, 5.0MM |

|---|---|

| WEIGHT | 5KG PER TUBE, 20KG PER CARTON |