Product Details

Description

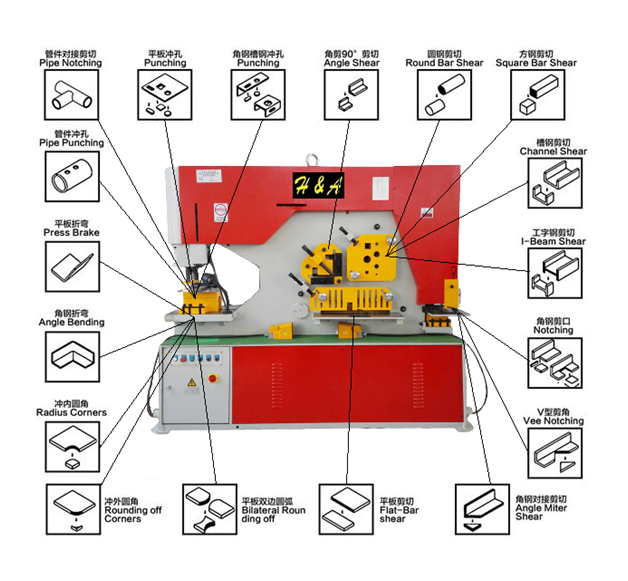

H&A HYDRAULIC IRONWORKER MACHINE Q35-16:

H&A牌子液压联合冲剪机Q35-16:

DESCRIPTION:

描述:

Q35Y series hydraulic ironworker adopts the hydraulic driving system. Ironworker can cut punch all kinds of holes. Various metal plates, square bar, angle steel, round iron, flat bar, profiled bars, channel steel and joist steel can be cut, punched, and notched on the machines.

There are multi-function machines combined as a hydraulic ironworker machine, for example, ironworker machine, press machine, steelworker machine, hydraulic ironworker machine, hydraulic steelworker machine, punching machine, and shearing machine.

Q35Y系列液压联合冲剪机采用液压驱动系统。铁工可用于打各种孔。各种金属板、方钢、角钢、圆铁、扁钢、异型钢、槽钢和龙骨钢均可在机器上切割、冲压和开槽。

一台液压联合冲剪机可代替多个功能机械,例如,铁工机、压力机、钢工机、液压铁工机、液压钢工机、冲孔机和剪切机。

VIDEO視頻:

MAIN FUNCTIONS:

主要功能:

| PUNCHING 冲孔 |

|

| SHEARING 剪切 |

|

| NOTCHING 开槽 |

|

OTHER FUNCTIONS:

其他功能:

TECHNICAL DATA:

技术数据:

| NO. 号码 | FUNCTIONS 功能 | VALVE 数值 | |

| 1 | SHEARING PLATE 剪板 | ANGLE OF SHEARING (°) 剪切角(°) | 7° |

| MAXIMUM SHEARING THICKNESS (MM) 最大剪切厚度(毫米) | 16 | ||

| FLAT BAR (MM) 扁钢(毫米) | 250 x 16 | ||

| 400 x 8 | |||

| 2 | SHEARING BAR 剪切杆 | ROUND STEEL (MM) 圆钢(毫米) | 45 |

| SQUARE BAR (MM) 四方刚(毫米) | 40 x 40 | ||

| 90° SHEARING OF EQUAL-ANGLE BAR (MM) 90°等角钢剪切(毫米) | 120 x 120 x 12 | ||

| 45°SHEARING OF EQUAL-ANGLE BAR (MM) 45°等角钢剪切(毫米) | 70 x 70 x 8 | ||

| 90°SHEARING OF T-BAR (MM) 90° T型钢剪切(毫米) | 120 x 120 x 12 | ||

| I-BEAM STEEL (MM) 工字钢(毫米) | 126 x 74 x 5 | ||

| CHANNEL STEEL (MM) 长钢(毫米) | 126 x 53 x 5.5 | ||

| 3 | NOTCHING 开槽 | THICKNESS (MM) 厚度(毫米) | 10 |

| WIDTH (MM) 宽度(毫米) | 80 | ||

| DEPTH (MM) 深度(毫米) | 100 | ||

| 4 | PUNCHING HOLE 冲孔 | MAXIMUM PUNCHING THICKNESS (MM) 最大冲孔厚度(毫米) | 16 |

| MAXIMUM DIAMETER OF PUNCHING (MM) 最大冲孔直径(毫米) | 25 | ||

| PUNCHING FORCE (TON) 冲孔压力(公吨) | 60 | ||

| DEPTH OF THROAT (MM) 喉口深度(毫米) | 300 | ||

| MAXIMUM LENGTH OF CYLINDER STROKE (MM) 最大行程长度(毫米) | 80 | ||

| STROKE TIMES (TIMES/MIN) 行程次数(次数/米) | 6 | ||

| 5 | MATERIAL STRENGTH (N/MM2) 板料强度(牛/平方毫米) | ≤450 | |

| 6 | MOTOR POWER (KW) 电机功率(千瓦) | 4 | |

| 7 | OVERALL DIMENSIONS (MM) – L X W X H 整体尺寸(毫米)- 长 X 宽 X 高 | 1650 x 800 x 1780 | |

| 8 | NET WEIGHT (KG) 净重(公斤) | 1900 | |