Product Details

Description

POWERWELD HARDFACING MN-NI HARDSURFACING ELECTRODE:

POWERWELD牌子硬质合金锰–镍硬表面电焊条:

DESCRIPTION:

描述:

- Tough, Work Hardenable Manganese Deposit.

- For Rebuilding And Reinforcing 11~14% Manganese Steels.

HARDFACING Mn-Ni is a smooth running, AC / DC electrode which deposits an austenitic manganese steel weld metal for rebuilding and reinforcing matching manganese and manganese/ nickel steels. Abrasion-resistant weld deposits such as HARDFACING ARC 33 can be applied directly onto HARDFACING Mn-Ni. Typical applications include the reclamation of crusher rods and jaws, bucket lips and teeth, grizzlies, liners, crossings and other manganese steel components. These electrodes is not recommended for direct application onto mild or carbon steels – in this situation STAINARC 309L should be used as a “buffer layer”.

- 坚韧,可硬化的锰矿床。

- 用于重建和加固11~14%的锰钢。

硬质合金锰-镍是一种运行平稳的交流/ 直流焊条,用于沉积奥氏体锰钢焊缝金属,用于重建和增强相匹配的锰和锰/镍钢。可以将诸如HARDFACING ARC 33之类的耐磨焊接熔敷物直接施加到硬质合金锰-镍上。常用于包括破碎机的杆和颚,铲斗的唇和齿,灰熊,衬里,叉车和其他锰钢部件的回收。不建议将这些电极直接应用到低碳钢或碳钢上–在这种情况下,应将STAINARC 309L用作“缓冲层”。

DEPOSIT PROPERTIES:

沉淀性质:

HARDFACING Mn-Ni deposits a semi-stabilized, austenitic manganese steel weld metal that work hardens under impact conditions. As the deposited weld is machinable and extremely tough, it offers excellent resistance to impact and high-stress gouging type abrasion.

硬质合金锰-镍沉积了一种半稳定的奥氏体锰钢焊接金属,该金属在冲击条件下会变硬。由于熔敷焊缝可加工且非常坚韧,因此具有出色的抗冲击性和高应力气刨型磨损。

TECHNICAL DATA:

技术数据:

Additional information

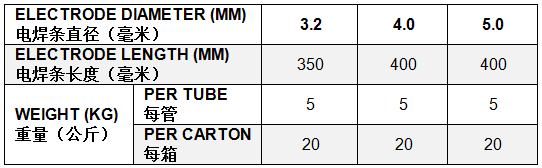

| ELECTRODE DIAMETER | 3.2MM, 4.0MM, 5.0MM |

|---|---|

| WEIGHT | 5KG PER TUBE, 20KG PER CARTON |